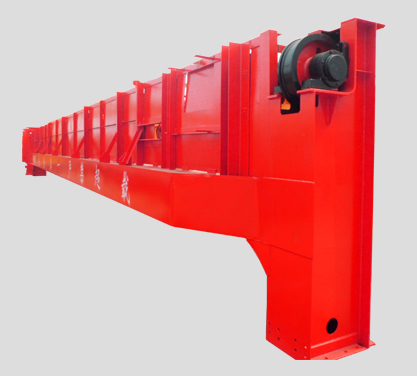

casting overhead crane mainly consists of main beam, hook trolley, crane traveling mechanism, cabin and electric controlling system, etc. Metallurgy overhead crane is one of the main equipment in the continuous casting technology of steel making. It is mainly used transfer the pouring melted iron to the appointed place, and the thermal-protective coating is added at the bottom of the main girder. The place where molten nonmetal material and red-hot solid metal is lifted. The casting overhead crane are heavy duty for 20-24hours working.

Hengyuan Group has rich metallurgy overhead crane production experience, and our QDY metallurgy overhead crane has sold very well in domestic and foreign market, and welcome to send us your inquiry at any time if you are interested in our machine, and we will try our best to satisfy your demand and requirements.

Features and Advantages:

Reasonable and compact structure, favorable performance, soft starting and stopping, safe and reliable traveling.

Low noise, commodious operation cabin and good view. Convenient maintenance and excellent interchangeability for parts and components.

It can greatly reduce energy consumption with advanced design and high quality components.

Product Parameter:

| Technical Data |

| Capacity |

10-320ton |

| Working class |

A7 |

| Span |

19-25m(According to your demands) |

| Max wheel load |

595KN |

| Lifting equipment |

crane crab |

| Lifting height |

Main hook |

18 |

20 |

25 |

24 |

20 |

| Auxiliary hook |

20 |

22 |

27 |

26 |

22 |

| Power supply |

380V/50Hz or as your requirement |

| Steel track Recommended |

QU120 or Other |

| Applicable occasions |

Lift molten metal, steel plant |

| Optional features |

• reless Radio Remote control |

|

| • rouded DSL system for power feeding |

|

| • ameproof Anti-explosion |

|

| • bin Operated |

|

| • automatic Control system |

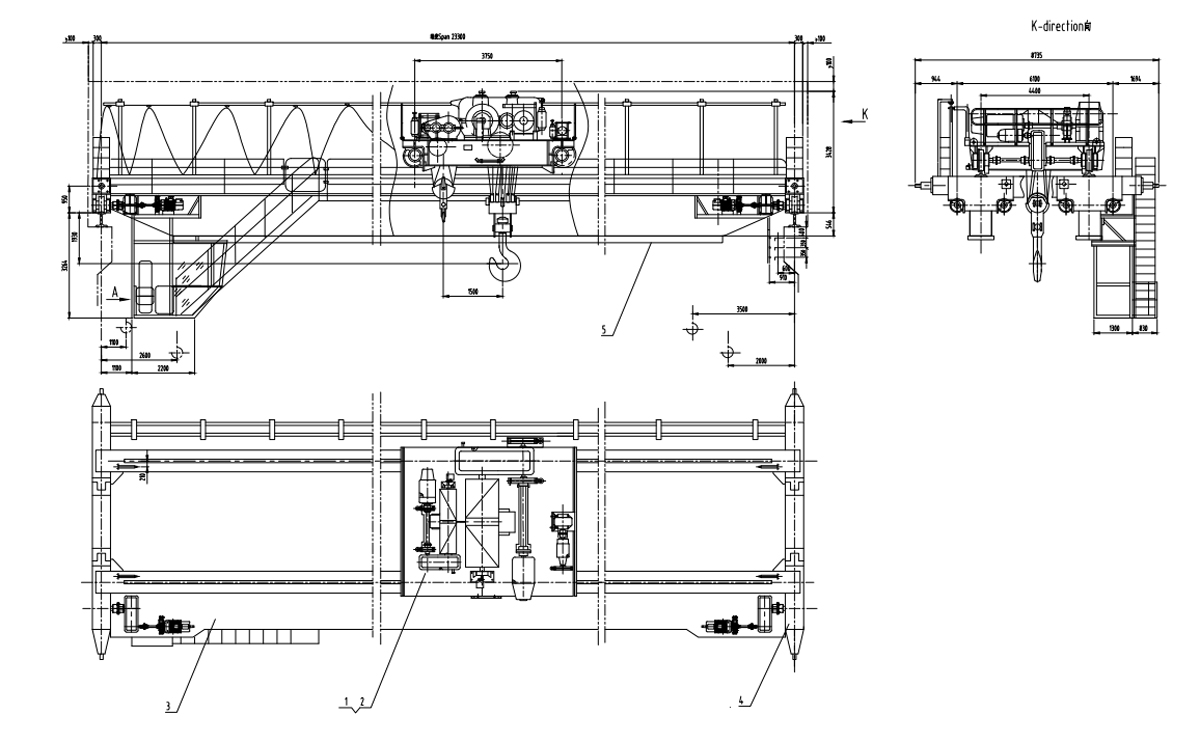

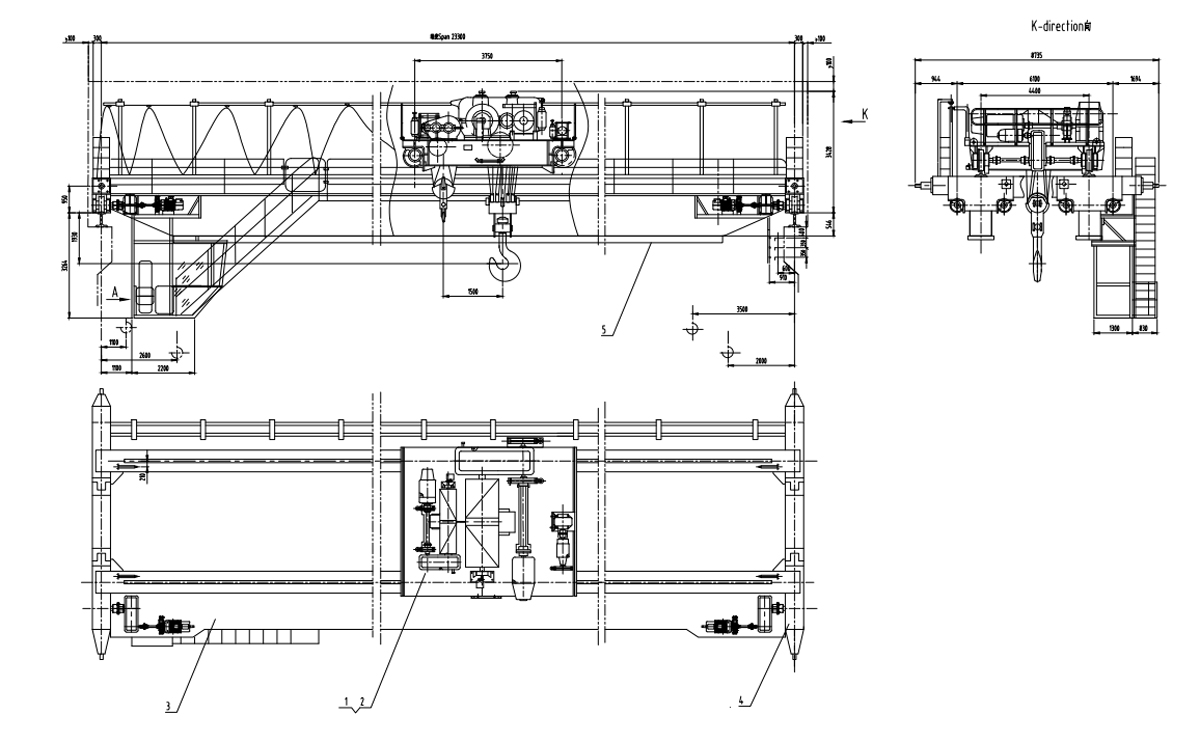

Schematic Drawing:

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.jpg)